MIL-DTL-23971D

4.6.1.3.2 Group B Rejected items. If an inspection lot is rejected, the contractor may rework it to correct the

defects, or screen out the defective units, and resubmit for reinspection. Such lots shall be separate from new lots,

and shall be clearly identified as reinspected lots.

4.6.1.3.3 Disposition of sample units. Sample items which have been subjected to group B inspection shall not be

delivered on the contract.

4.6.1.3.4 Noncompliance. If a sample fails to pass group B inspection, the manufacturer shall notify the acquiring

activity of such failure and take corrective action on the materials or processes, or both, as warranted, and on all units

of product which can be corrected and which were manufactured under essentially the same conditions with

essentially the same materials and processes, and which are considered subject to the same failure. Acceptance

and shipment of product shall be discontinued until corrective action, acceptable to the acquiring activity, has been

taken. After the corrective action has been taken, group B inspection shall be repeated on additional sample units (all

inspections, or the inspection which the original sample failed, at the option of the acquiring activity. Group A

inspection may be reinstated; however, final acceptance and shipment shall be withheld until the group B

re-inspection has shown that the corrective action was successful. In the event of failure after re-inspection,

information concerning the failure and the corrective action taken shall be furnished to the cognizant acquiring activity

(see 6.4).

4.7 Methods of inspection.

4.7.1 Visual and mechanical inspection. The items shall be examined to verify that the material, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements

4.7.2 Seal.

4.7.2.1 Hermetic seal (see 3.6.1.1). Hermetically sealed items shall be tested in accordance with MIL-STD-202,

method 112. The following apply:

a.

Test conditions letter: C.

b.

Procedure: III.

c.

Degree of leakage rate sensitivity (see 3.6.1.1).

4.7.2.2 O-ring, solder seal, or encapsulated or enclosed seal (see 3.6.1.2). O-ring seal, solder seal, or

encapsulated sealed items shall be tested in accordance with MIL-STD-202, method 104. The following applies:

a.

Test condition letter: B.

4.7.3 Average coupling (see 3.5.1). The average coupling of the item shall be determined by the sweep frequency

technique over the specified frequency range (see 3.1) using the test setup of figure 1 or equivalent. The nominal

coupling loss for each type of toroidal, stripline and micro-strip power divider shall be as follows:

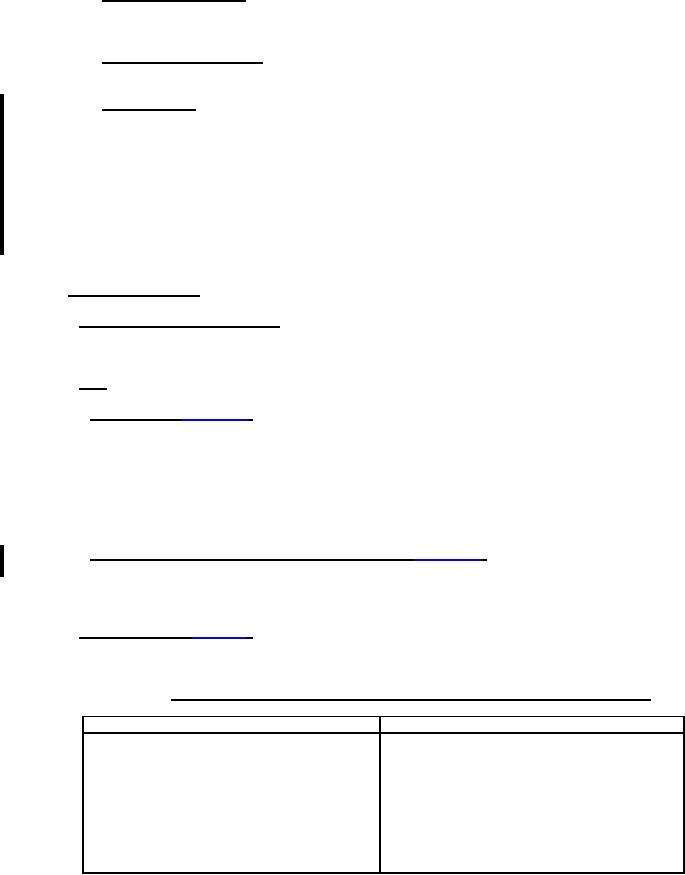

Table VII. Nominal coupling loss values for toroidal, stripline and micro-strip power dividers.

Type of power divider

Nominal coupling loss (dB)

2-Way

3.01

Resistive Loaded 2-Way

6.0

3-Way

4.77

4-Way

6.02

6-Way

7.78

8-Way

9.03

12-Way

10.80

16-Way

12.04

24-Way

13.80

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business