MIL-DTL-3890C

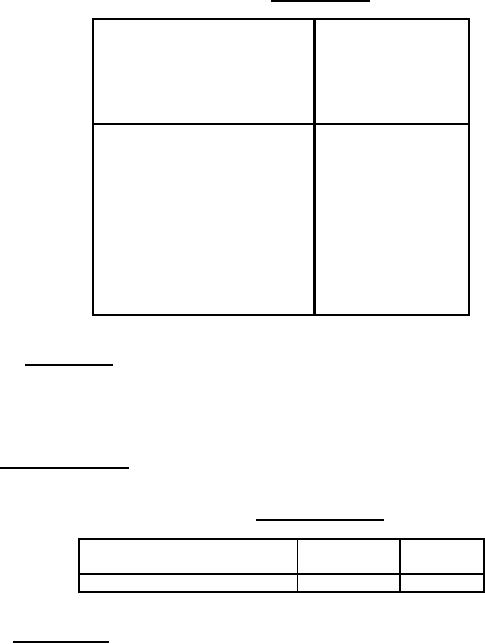

TABLE V. Inspection level.

Visual and

Lot size

mechanical

inspection

1

to

15

Amount produced

280

16

16

to

1,200

47

281

to

3,200

53

1,201

to

10,000

68

3,201

to

35,000

77

10,001

to

150,000

96

35,001

to

500,000

119

150,001

to

143

500,001

to

over

4.4.1.2.1.1 Rejected lots. If an inspection lot is rejected after group A and B inspection, the lot shall

not be supplied to the contract order or purchase order. In cases where the defect(s) are minor in nature,

such as smudged marking, the contractor may contact the qualifying activity for permission to screen the

lot to remove defective parts or rework the lot. The qualifying activity shall be contacted for guidance in

such situations. Rejected lots shall be kept separate and shall not lose their identity.

4.4.1.3 Group B inspection. Group B inspection shall consist of the test specified in table VI and shall

be made on sample units which have been subjected to and have passed the group A inspection.

TABLE VI. Group B inspection.

Test

Requirement

Method

paragraph

paragraph

Dielectric withstanding voltage

3.10

4.5.7

4.4.1.3.1 Sampling plan. A sample of parts shall be randomly selected in accordance with table VII. If

one or more defects are found, the lot shall be screened for that particular defect and defects removed.

After screening and removal of defects, a new sample of parts shall be randomly selected and subjected

to all tests in accordance with table VII. If one or more defects are found in the second sample, the lot

shall be rejected and shall not be supplied to this specification.

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business