MIL-DTL-23971D

4.7.20 Salt atmosphere (see 3.6.11). This test may be performed on empty flatpacks or pin packages. The item

a.

Apply salt solution: 5 percent.

b.

Test condition: B.

After test, dry specimens for 24 hours ± .5 at 40°C.

c.

d.

Inspect item for corrosion.

4.7.21 Sand and dust (see 3.6.12). The item shall be tested in accordance with method 110 of MIL-STD-202, test

condition A. At completion of the exposure period, the device shall be tested for phase balance, amplitude balance,

4.7.22 Explosion (see 3.6.13). The item shall be tested in accordance with method 109 of MIL-STD-202 under

rated load (see 3.1).

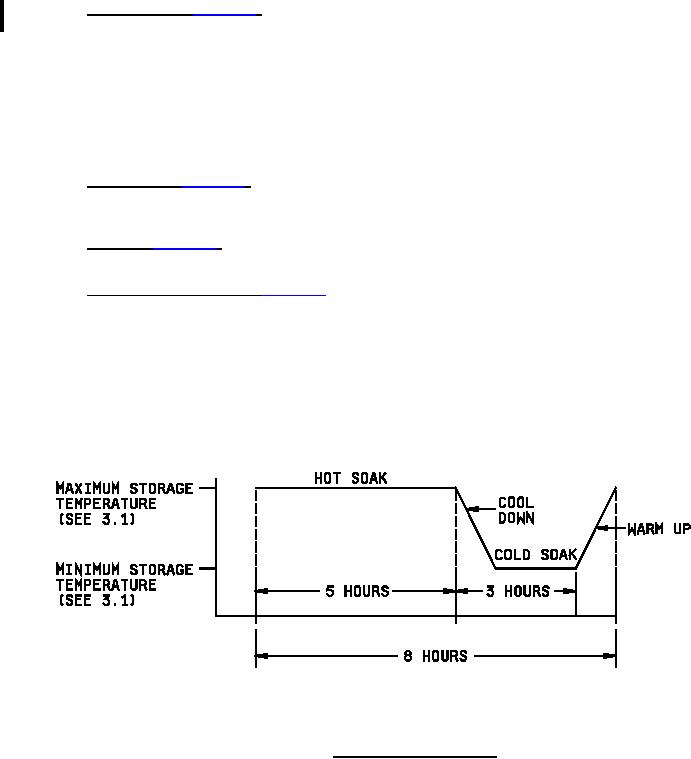

4.7.23 Temperature cycling screen (see 3.6.14). Temperature cycling screen test shall be conducted using an air

atmosphere test chamber, in accordance with MIL-STD-810, and with the following guidelines. Number of

temperature cycles shall be ten (10). Each temperature cycle (see figure 6) includes hot and cold temperature soaks,

wherein the test item temperature stabilizes within ± 2°C of high and low temperature extremes (maximum and

minimum storage temperatures (see 3.1), respectively). Temperature extremes are separated by part cool down and

warm up temperature change rate periods of 20°C per minute, chamber permitting. Warm up is included in the "5

hours" interval of the 8 hour cycle. Test items should be non-operating during temperature cycling. VSWR (4.7.4),

insertion loss (4.7.5) and isolation (4.7.6) tests should be conducted following the temperature cycling screen to

confirm success or failure.

FIGURE 6. Temperature cycling profile.

20

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business