MIL-DTL-85/2F

Bow: In accordance with MIL-DTL-85, except the bow, for any orientation, shall be no more than .015 inch (0.38

mm) edgewise and .020 inch (0.51 mm) flatwise between any two points 2 feet apart on the concave external surface

of the waveguide.

PIN: See table I.

Material: See table II.

NOTES:

Resistivity and conductivity of materials: See table II.

Frequency range and engineering information: See table III.

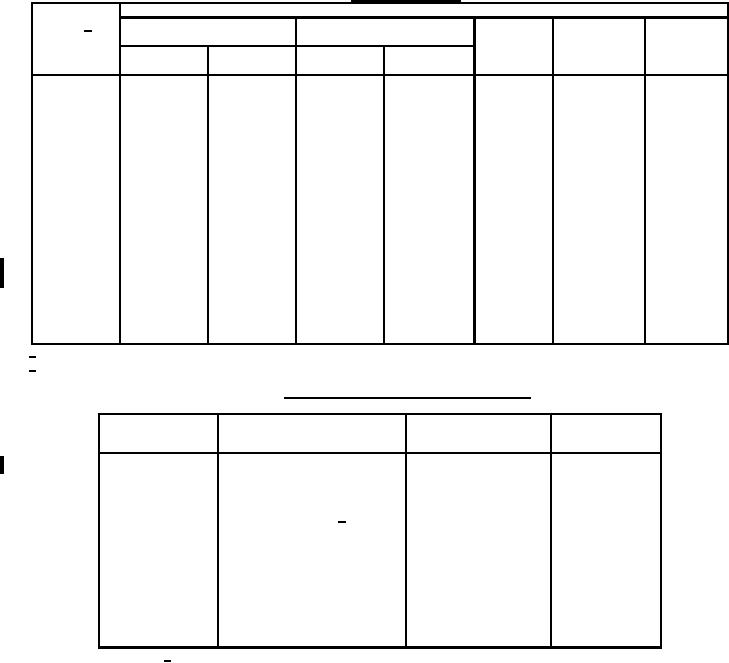

TABLE I. Physical dimensions.

Dimensions

PIN 1/

Nominal

M85/2-

Inside

Outside

wall

Max. inner

Max. outer

Width

Height

Width

Height

thickness

corner radius

corner radius

(A)

(B)

(C)

(D)

(E)

(F)

(G)

2.840 ± .005

1.340 ± .005

3.238 ± .004

1.738 ± .005

001, 002, 004

.199

.0468

.125

(5.05)

(1.19)

(3.18)

(72.14) (0.13) (34.04) (0.13) (82.25) (0.10)

(44.15) (0.13)

1.872 ± .005

.872 ± .005

2.172 ± .005

1.172 ± .005

003, 005

.150

.0310

.125

(3.81)

(0.79)

(3.18)

(47.54) (0.13) (22.14) (0.13) (55.16) (0.13)

(29.76) (0.13)

1.872 ± .003

.872 ± .003

2.122 ± .005

1.122 ± .005

006

.125

.030

.031

(3.18)

(0.76)

(0.79)

(47.54) (0.07) (22.14) (0.07) (53.90) (0.13)

(28.50) (0.13)

1.122 ± .003

.497 ± .003

1.378 ± .005

.753 ± .005

007

.128

.030

.031

(3.25)

(0.76)

(0.79)

(28.50) (0.07)

(12.62 (0.07)

(35.00) (0.13)

(19.12) (0.13)

.900 ± .003

.400 ± .003

1.100 ± .005

.600 ± .005

008

.100

.030

.031

(2.54)

(0.76)

(0.79)

(22.86) (0.07) (10.16) (0.07) (27.94) (0.13)

(15.24) (0.13)

.900 ± .003

.400 ± .003

1.300 ± .005

.800 ± .005

009

.200

.030

.031

(5.08)

(0.76)

(0.79)

(22.86) (0.07) (10.16) (0.07) (33.01) (0.13)

(20.32) (0.13)

1/ The complete PIN shall be the number shown and a three-digit number indicating length in inches (e.g. M85/2-001-240).

2/ Metric equivalents (to the nearest .01 mm) are given for general information only and are based upon 1 inch = 25.4 mm.

Metric equivalents are given in parentheses.

TABLE II. Typical resistivity and conductivity of materials.

PIN

Material

Resistivity (microhm-cm)

Conductivity

max at 20°C)

M85/2-

Aluminum (ASTM-B210)

001-xxx

Alloy 1100

2.90

57 percent

002-xxx

Alloy 6061

4.00

40 to 45 percent

003-xxx

Alloy 1100 1/

2.90

57 percent

004-xxx

Alloy 6063

3.40

50 percent

005-xxx

Alloy 6063

3.40

50 percent

006-xxx

007-xxx

OF-DLP copper

008-xxx

in accordance

1.77

101 percent

009-xxx

with ASTM-B372

1/ Temper shall be H112 with a minimum tensile strength of 11,000 pound-force

2

per square inch (lbf/in )(75.842 MPa).

2