MIL-DTL-85/2F

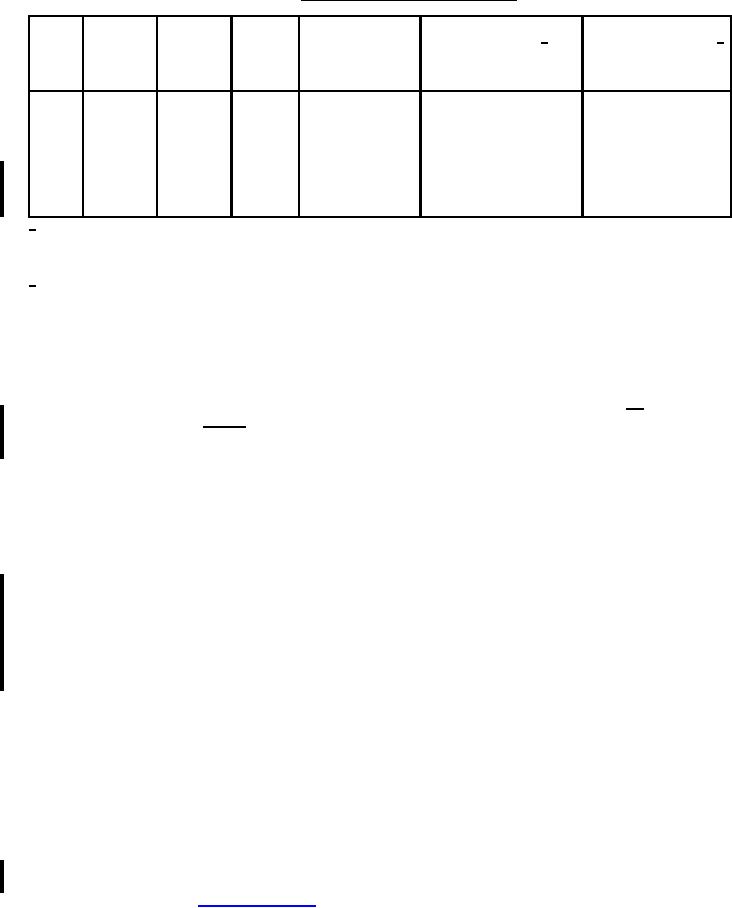

TABLE III. Cross index and engineering information.

Cutoff

AN

Frequency

Theoretical

Theoretical CW 1/

Theoretical peak power 2/

forTE10

PIN

type

attenuation lowest to

range (GHz)

power rating

rating lowest to highest

mode

M85/2-

designation TE mode

highest frequency

lowest to highest frequency

frequency (megawatts)

(GHz)

10

(dB/100 ft)

(kilowatts)

001-xxx RG-375/U 2.60 - 3.95

2.08

.950 - 0.651

14.56 - 21.25

7.645 - 10.85

002-xxx

---

2.60 - 3.95

2.08

1.116 - 0.764

12.39 - 18.08

7.645 - 10.85

003-xxx

---

3.95 - 5.85

3.155

1.785 - 1.238

5.637- 8.127

3.296 - 4.697

004-xxx

---

2.60 - 3.95

2.08

1.028 - 0.705

13.48 - 19.63

7.645 - 10.85

005-xxx

---

3.95 - 5.85

3.155

1.933 - 1.340

5.206 - 7.506

3.296 - 4.697

006-xxx

---

3.95 - 5.85

3.155

1.399 - 0.970

6.961- 10.05

3.296 - 4.697

007-xxx

---

7.05 - 10.0

5.780

2.779 - 2.159

2.382 - 3.006

1.284 - 1.702

008-xxx

---

8.20 - 12.40

6.560

4.339 - 3.003

3.314 - 4.788

0.758 - 1.124

009-xxx

---

8.20 - 12.40

6.560

4.339 - 3.003

3.314 - 4.788

0.758 - 1.124

1/ Based on H. E. King, "Rectangular Waveguide Theoretical CW Average Power Rating", IRE Transactions PGMTT-9,

pp. 349-357, July 1961. Assumes 1:1 VSWR, 30°C ambient air and 71°C waveguide temperature (governed by personnel

safety requirements). To calculate for other situations, see H. E. King.

2/ Based on considerations of breakdown varying with frequency and waveguide size as outlined in Gould and Gilden's

"Handbook of High Power Capabilities of Waveguide Systems" (available from Microwave Associates, Burlington, MA). For

practical applications, these values should be reduced by a factor of 5.

SAMPLING AND INSPECTION:

All waveguides of the same material and same cross section offered for delivery at one time shall be considered a

lot: N - pieces (lengths).

Inspection of dimensions and visual inspection of surface shall be performed on a sample of n = √2� (e.g., If N =

200 pieces, the sample n = √2 ∗ 200 = 20 pieces.)

The sample for profilometer measurement of surface roughness and eccentricity shall be 1 foot in length, cut from

either end of a selected length.

The lot shall be accepted or rejected in accordance with a zero defective sampling plan. Lots that fail shall be 100

percent inspected for the defect identified and then resampled.

Referenced documents. In addition to MIL-DTL-85, this document references the following:

MIL-PRF-3150

ASTM-B210

ASTM-B372

The margins of this specification sheet are marked with vertical lines to indicate where modifications from this revision

were made. This was done as a convenience only and the Government assumes no liability whatsoever for any

inaccuracies in these notations. Bidders and contractors are cautioned to evaluate the requirements of this document

based on the entire content irrespective of the marginal notations

Custodians:

Preparing activity:

Army - CR

DLA - CC

Navy - EC

Air Force - 85

(Project 5985-2014-013)

Review activities:

Army - AR

Navy - AS, MC, OS

Air Force - 99

NOTE: The activities listed above were interested in this document as of the date of this document. Since

organizations and responsibilities can change, you should verify the currency of the information above using the

ASSIST Online database at https://assist.dla.mil/.

3