MIL-DTL-22641F

4. VERIFICATION

4.1 Test equipment and inspection facilities. Test and measuring equipment and inspection facilities of sufficient

accuracy, quality, and quantity to permit performance of the required inspection shall be established and maintained

by the supplier. The establishment and maintenance of a calibration system to control the accuracy of the measuring

and test equipment shall be in accordance with NCSL-Z540.3.

4.2 Classification of inspections. The inspections specified herein shall be classified as follows:

(a) First article inspection (see 4.4).

(b) Conformance inspection (see 4.5).

(1) Inspection of product for delivery (see 4.5.1).

4.3 Inspection conditions. Unless otherwise specified herein, all inspections shall be performed in accordance with

the test conditions specified in the "GENERAL REQUIREMENTS" of MIL-STD-202.

4.4 First article inspection. First article inspection shall be performed by the supplier, after award of contract and

prior to production, at a location acceptable to the Government. First article inspection shall be performed on sample

units that have been produced with equipment and procedures normally used in production. First article approval is

valid only on the contract or purchase order under which it is granted, unless extended by the Government to other

contracts or purchase orders (see 6.4).

4.4.1 Sample size. Three adapters shall be subjected to first article inspection.

4.4.2 Inspection routine. The samples shall be subjected to the inspections specified in table I, in the order shown.

All units shall be subjected to and pass visual and mechanical examination.

4.4.3 Failure. One or more failure shall be cause for refusal to grant first article approval.

4.4.4 Disposition of first article. Sample units which have been subjected to first article testing shall not be

delivered on any contract or purchase order. The Government (see 6.4) reserves the right to retain the sample units

or to require the contractor to furnish the sample units with the first article inspection report.

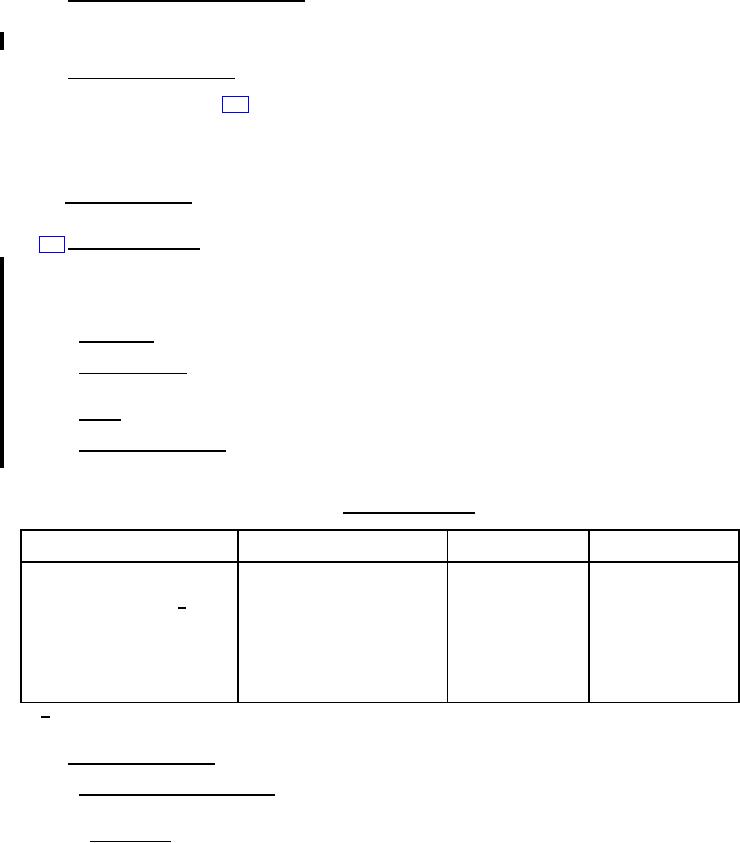

TABLE I. First article inspection.

Examination or test

Requirement paragraph

Method paragraph

Number of samples to

inspect

Visual and mechanical exam

3

VSWR

3.4

3

RF insertion loss 1/

3.5

3

Pressurization

3

Shock (specified pulse)

3.7

3

Vibration

3.8

3

Salt atmosphere (corrosion)

4.6.7

3

Dielectric withstanding voltage

4.6.8

3

Gauge (as specified)

3

1/ When specified.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B

inspection.

4.5.1.1 Inspection lot. An inspection lot shall consist of all adapters of the same PIN, produced under essentially

the same conditions, and offered for inspection at one time.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business