MIL-DTL-24211C

3.8 Workmanship. Gaskets shall be processed in such a manner as to be representative of controlled Industrial

techniques, and all surfaces shall be free from burrs, die marks, chatter marks, scratches, dirt, grease, scale,

splinters, and other defects that will affect life, serviceability, or appearance.

4. VERIFICATION

4.1 Test equipment and inspection facilities. Test equipment and inspection facilities shall be of sufficient

accuracy, quality, and quantity to permit performance of the required inspection. The manufacturer shall establish

and maintain calibration of inspection equipment to the satisfaction of the Government. Calibration of the standards

which control the accuracy of inspection equipment shall comply with the requirements of NCSL-Z540.3.

4.2 Classification of inspections. The inspection requirements specified herein are classified as follows:

a. Component materials inspection (see 4.3).

b. Conformance inspection (see 4.5).

(1) Inspection of product for delivery (see 4.5.1).

4.3 Component materials inspection. Materials inspection shall consist of verification that the component

materials (see 3.2 through 3.2.2, 3.3.1, 3.7, 4.6.1 and table I) used in fabricating the waveguide gaskets, are in

accordance with the applicable referenced specifications or requirements prior to such fabrication (see 3.7).

4.4 Inspection conditions. Unless otherwise specified herein, all inspections shall be performed in accordance

with the test conditions specified in MIL-STD-202.

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of group A and group B

inspections.

4.5.1.1 Inspection lot. An inspection lot, as far as practicable, shall consist of all the gaskets of the same part

number, produced under essentially the same conditions and offered for inspection at one time.

4.5.1.2 Rejected lots. If an inspection lot is rejected, the manufacturer may withdraw the lot, rework it to correct

the defects, or screen out the defective units, as applicable, and re-inspect. Such lots shall be kept separate from

new lots and shall be clearly identified as re-inspected lots. Rejected lots shall be inspected using tightened

inspection.

4.5.1.3 Group A inspection. Group A inspection shall consist of the examinations specified in table II; all group A

examinations shall be made on the same set of sample units.

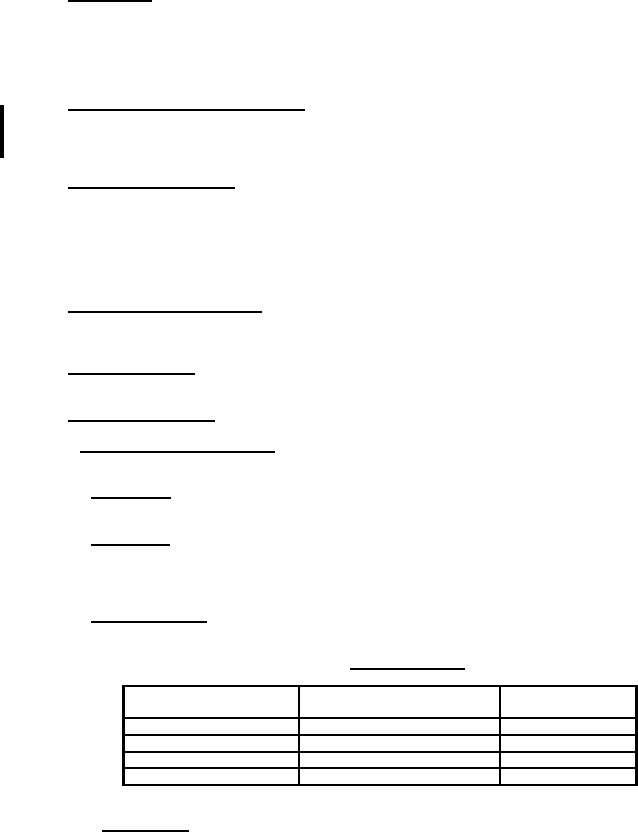

TABLE II. Group A inspection.

Examination

Requirement paragraph

Method

paragraph

Visual and mechanical

--

Material

Interface

Workmanship

3.8 4.6.1

4.5.1.3.1 Sampling plan. Statistical sampling and inspection shall be performed on an inspection lot basis with a

random sample of gaskets selected in accordance with table III. The acceptance levels shall be based upon the

zero defective sampling plan. No failures shall be permitted.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business