MIL-DTL-24211C

4.5.1.4.2 Noncompliance. If a sample fails to pass group B inspection, the manufacturer shall take corrective

action on the materials, process, or both, as warranted, and on all units of product which can be corrected and which

were manufactured under essentially the same conditions, with essentially the same materials, and processes, and

which are considered subject to the same failure. Acceptance of the product shall be discontinued until corrective

action, acceptable to the Government, has been taken. After the corrective action has been taken, group B

inspection shall be repeated on additional sample units (all inspection, or the inspection which the original sample

failed, at the option of the government). Group A inspection may be re-instituted; however, final acceptance shall be

withheld until the group B inspection has shown that the corrective action was successful.

4.5.1.4.3 Disposition of samples. Sample units which have been tested under the group B inspection shall not be

delivered on the contract or purchase order.

4.6 Methods of examination and test.

4.6.1 Visual and mechanical examination. Gaskets shall be examined to verify that the materials, design,

interface, physical dimensions, plating and workmanship are in accordance with the applicable requirements (see

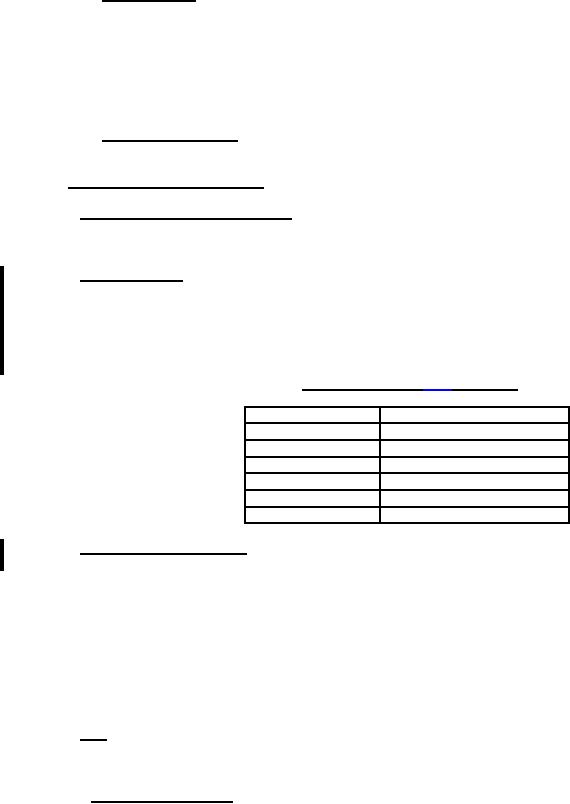

4.6.2 Rubber adhesion. A gasket shall be mounted between two applicable flanges with torque, as specified in

table VI applied to the mounting bolts. Thermal shock shall be conducted in accordance with method 107, test

condition B of MIL-STD-202. After cycling, the temperature shall be raised to 190o C and held for 20 hours and then

o

lowered to -40 C and held for 4 hours, after which the gasket shall be removed and inspected. There shall be no

evidence of the rubber s being permanently deformed or coming loose from the gasket. The rubber seal must meet

or exceed the performance requirements of the materials required in 3.2.2.

Bolt size

Torque (inch pounds)

4-40

4.5

6-32

8.5

8-32

18.0

10-24

23.0

¼-20

80.0

5/16-18

140.0

4.6.3 Salt atmosphere (corrosion). Gaskets shall be tested in accordance with method 101 of MIL-STD-202. The

following details shall apply:

a. The specimen shall be mounted between two applicable flanges attached to waveguide pieces

which are sealed on the ends. Torque as indicated in table IV shall be applied to the mounting bolts.

b. Test condition B.

c. Before the salt deposit is removed, the gasket shall be removed and examined. There shall be no salt

on the flange or gasket from the center of the rubber seal inward. The gasket shall then be washed and

examined. The requirements of 3.3.1 shall be met.

4.6.4 Seal. Gaskets shall be tested in accordance with method 112 of MIL-STD-202, test condition A. Tap water

is to be used instead of oil. Observation is to be for a minimum of 2 minutes. After adhering air bubbles have been

removed, and further escaping bubbles indicate a bad seal, the item shall be rejected.

4.6.4.1 Seal (alternate method).

a. Gaskets shall be mounted by the same method as in 4.6.3, except one waveguide piece shall be

provided with a fitting for applying compressed air or nitrogen.

b. The bolted assembly shall be immersed in water and pressurized with air or nitrogen to 15 psig.

c. Gaskets shall pass visual inspection as in 4.6.1 during and after seal test.

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business